Top five Rules in Rock crushing process Stone Crusher

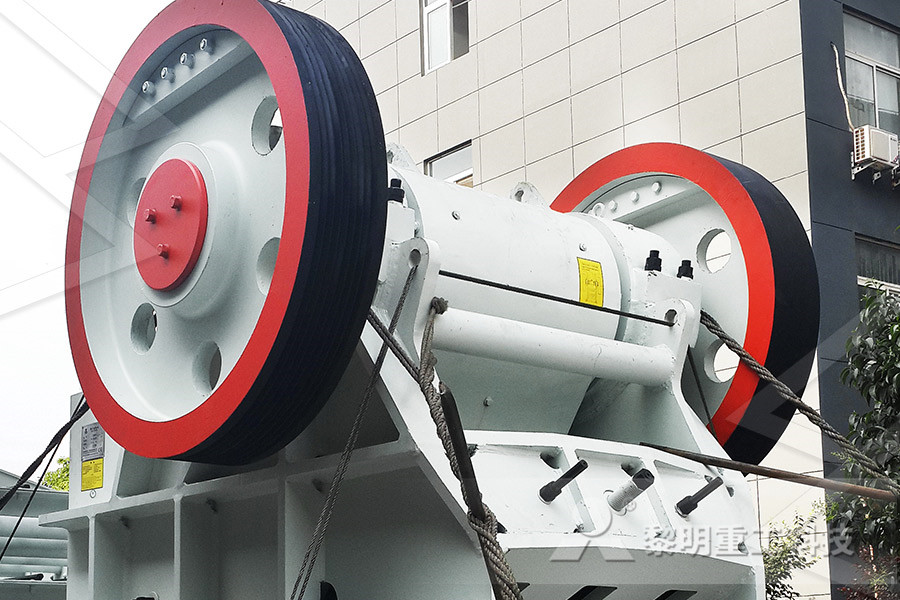

Jan 05, 2012 Rock crushing process Rock crushing process involves many plants, such as jaw crusher for primary crushing stage, impact crusher for secondary crushing stages, and also other crushing plants such as cone crusher, vertical crusher, ball mill, raymond mill etcJul 18, 2015 First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to The crusher “breaks it and the fine material produced will drop through the gap between the mantle and the liner as it opens The coarse material that can’t fall through will remain to be crushed Rock Crushing Process in Mining11/95 Sand And Gravel Processing 111911 11191 Sand And Gravel Processing 111911 Process Description16 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural disintegration of rock or stone, are generally found in nearsurface alluvial deposits and in subterranean and subaqueous beds11191 Sand And Gravel ProcessingJust enough explosive is used in blasting to break the rock from the face A powerful excavator loads the rock into dump trucks for delivery to the primary crusher Crushing Powerful hammers or metal jaws within the primary crusher break the rock down Rock passes through a Extraction of Aggregates Process CEMEX USA CEMEXDec 02, 2020 Mechanical sand is natural rock with mechanical crushing, being made after screening And mixed sand is a mixture of natural sand and artificial sand with no fixed mixing ratioHow to Process Sandgravel Aggregate?

Types of Rock Crushers Quarry Crushing Equipment Kemper

Apr 22, 2020 Stages of Rock Crushing: Crushing Stations It is common to use multiple crusher types within a project and set them up as stations in a circuit format to Mar 23, 2015 process rock, sand, gravel, or mineral aggregate or that mines rock, stone, sand and gravel for construction As screening and conveying equipment After crushing, the rock is sorted according to size in screeners and conveyed to storage piles by conveyors Front end loaders and trucks are used to move finished materialsUnited States Environmental Protection Agency General Understanding the stages of crushing process and the types of crushers that best fit each stage can simplifies your equipment selection Each type of crusher is different and used to achieve a certain end result Similarly, a certain output is expected at the end of each crushing stage for the next phase of the processRock crushing equipment for sale Eastman Rock CrusherCrushing processing sandstone sandstone crushing processing technology at present mainly has the following kinds 1, crushing process directlyIts technological process is: the run of mine ore – grizzly – jaw crusher crushing and screening to cone crushing and screening, more paragraphs to roll the crushing and screening – productsSilica Mining Processing Equipment Flow Chart Cases Ganzhou Eastman Technology Co, Ltd has for the target market in selling mineral processing equipment for rock crushing/grinding and sand making/washing operations We provide those machines directly from our owned manufacturing workshop located in Shangyou factory or Rock Crushing Sand Making Machine for Sale Eastman

11191 Sand And Gravel Processing

11/95 Sand And Gravel Processing 111911 11191 Sand And Gravel Processing 111911 Process Description16 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural disintegration of rock or stone, are generally found in nearsurface alluvial deposits and in subterranean and subaqueous bedsCrushing Crushing is often one of the first steps in the production of rock, coal and other minerals, as mined material can consist of boulders that are too big to fit through the processing plant The type of crusher required depends on the material being reducedCrushing McLanahanJust enough explosive is used in blasting to break the rock from the face A powerful excavator loads the rock into dump trucks for delivery to the primary crusher Crushing Powerful hammers or metal jaws within the primary crusher break the rock down Rock passes through a Extraction of Aggregates Process CEMEX USA CEMEXNov 01, 2018 As with the Sandvik CV series, the Barmac VSI is also ideal for the manufacturing of sand from rock and uses the rock fed into the machine as the crusher This autogenous crushing action (as with Sandvik’s CV series) offers the lowest possible cost/tonne of any impact crushing Crushing and screening for sustainable excavationSilica sand mining process equipment flow process Crushing processing sandstone sandstone crushing processing technology at present mainly has the following kinds 1, crushing process directlyIts technological process is: the run of mine ore – grizzly – jaw crusher crushing and screening to cone crushing and screening, more paragraphs to Silica Mining Processing Equipment Flow Chart Cases

Types of Rock Crushers Quarry Crushing Equipment Kemper

Do you need to process sand, gravel, minerals, rock, or other aggregate products and have not yet purchased or leased crushing equipment? There’s no question—you need to work with a capable and professional material handling equipment design and engineering company dedicated to selling, renting, and installing the best new crushers for your needsThe impact crusher is widely used for sand and rock fine crushing in the industry of roads, railways, reservoir, electricity power and building materials and so on And the compressive strength less than 350 MPa 3 Working Principle Jaw rock crusher does cyclical movement by swinging jaw to crusher rockImpact Crusher Rock Crusher Machine Manufacturer JXSC MineMar 23, 2015 process rock, sand, gravel, or mineral aggregate or that mines rock, stone, sand and gravel for construction As screening and conveying equipment After crushing, the rock is sorted according to size in screeners and conveyed to storage piles by conveyors Front end loaders and trucks are used to move finished materialsUnited States Environmental Protection Agency General Feb 22, 2012 Impact and jaw crushers were primarily developed for the reduction of hard materials, such as rock and concrete rubble, where a highenergy input is required for the crushing process The use of such machines in the recycling of reclaimed asphalt tends to result in fragmentation of the aggregates within the asphalt and the production ofAsphalt Crushing and Recycling plant Stone Crusher used areas; cutting stone The wastewater generated at these quarries consists of runoff from the rock and sand crushing/washing process, vehicle/equipment washing and maintenance areas, and stormwater runoff from the active quarry (direct contact)(a) The wastewater generated at stone cutting facilities consists of wastewater used to cool theFACT SHEET GENERAL WASTEWATER PERMIT FOR ROCK,

How to Process Sandgravel Aggregate?

Dec 02, 2020 Then use a jaw crusher to crush them The jaw crusher uses the movement of the jaw plate to crush the large aggregate of sand and gravel into smaller particles The raw material will be transported to the transit heap by the conveying equipment Then use the sand making machine to turn the materials into fine plastic, sand and stone aggregateThe cone crusher (a compression type) simply crushes the aggregate between the oscillating cone and the crusher wa ll (Figure 59) Clearance settings on this equipment are required to be checked and maintained as part of standard operating procedure Figure 59 Cone Crusher5 Aggregate Production inJul 11, 2020 The process of crushing machinemade sand includes dry sand making and wet sand making Both methods can produce highquality sand and gravel The wet sand making machine can clean the sand and gravel very cleanly, and it can also recycle the sand Dry sand making equipment is relatively simple and does not need to consume a lot of water forConstruction waste crusher for sand making LZZGEach plant would incorporate one or several crushing machines depending on the required final material, gravels or sand or both Generally jaw crushers and Gyratory crushers are used for primary crushing, while impact crusher, Symons cone crusher, hammer crusher are used for secondary crushing and tertiary crushingCrusher Plant Henan Deya Machinery Co, LtdEquipment employed during the process of crushing and sand making of mountain rocks: relatively hard and big mountain rocks can be crushed by jaw crusher and impact crusher together And which kind of equipment will be choose finally depends on input size, hardness of the raw material, and final size of the product three factorsWhich type of Sand Making MachinerySand Making ProcessSand Crushing

11191 Sand And Gravel Processing

11/95 Sand And Gravel Processing 111911 11191 Sand And Gravel Processing 111911 Process Description16 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural disintegration of rock or stone, are generally found in nearsurface alluvial deposits and in subterranean and subaqueous bedsJust enough explosive is used in blasting to break the rock from the face A powerful excavator loads the rock into dump trucks for delivery to the primary crusher Crushing Powerful hammers or metal jaws within the primary crusher break the rock down Rock passes through a Extraction of Aggregates Process CEMEX USA CEMEXThe cone crusher (a compression type) simply crushes the aggregate between the oscillating cone and the crusher wa ll (Figure 59) Clearance settings on this equipment are required to be checked and maintained as part of standard operating procedure Figure 59 Cone Crusher5 Aggregate Production inCrushing Crushing is often one of the first steps in the production of rock, coal and other minerals, as mined material can consist of boulders that are too big to fit through the processing plant The type of crusher required depends on the material being reducedCrushing McLanahanDec 02, 2020 Then use a jaw crusher to crush them The jaw crusher uses the movement of the jaw plate to crush the large aggregate of sand and gravel into smaller particles The raw material will be transported to the transit heap by the conveying equipment Then use the sand making machine to turn the materials into fine plastic, sand and stone aggregateHow to Process Sandgravel Aggregate?

Types of Rock Crushers Quarry Crushing Equipment Kemper

Do you need to process sand, gravel, minerals, rock, or other aggregate products and have not yet purchased or leased crushing equipment? There’s no question—you need to work with a capable and professional material handling equipment design and engineering company dedicated to selling, renting, and installing the best new crushers for your needsrock sand making machinery in china AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plantrock sand making machinery in chinaStone Crushing Plant is complete unit for crushing and classify rocks in a quarry, in construction and mining industry, stone crushing and screening plant is indispensable machine In the mining industry, crushing plant breaks the ore to a small size, and then grind the smaller size according to process requirements, finally, the material is Stone Crushing Plant, Rock Crushers, Stone Crushers Our company is a largescale mining machinery production and export base, mainly including six major categories of equipment: crushing and screening, sand washing, mineral processing, building materials, industrial milling and mobile crushing plants And our company can also tailor the crushing sand production line and beneficiation process according to the specific needs of customersSand Making Machine,Stone Crusher,Jaw Apartmenthubmetalshredding –miningmachinery mobilerock crusher February 2, 2021 mobilecrusherline Leave a Comment on Metal Shredding Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for process for mining rock crusher sand metal Bussa Machinery

Modern controls, system integrator automate rock crushing

Oct 15, 2019 Figure 2: The dry process vertical shaft impact crusher uses twin 400 hp motors to crush 15in rock to 1/8in minus sand that is fed to the wet plant Source: AutomationDirect The dry process features a primary crusher handling material brought into the plantEach plant would incorporate one or several crushing machines depending on the required final material, gravels or sand or both Generally jaw crushers and Gyratory crushers are used for primary crushing, while impact crusher, Symons cone crusher, hammer crusher are used for secondary crushing and tertiary crushingCrusher Plant Henan Deya Machinery Co, LtdThe comminution is an important unit operation in mineral processing, this process requires application of forces Mechanical comminution can be accomplished in mainly 2 ways 1 Crushing: the most used crushing machine are the jaw crusher, cone crusher, impact crusher, and hammer crusher 2 Grinding: crushed material can be further ground in grinding mills like ball mill, rod mill, hammer Equipment for Mineral Comminution Process Mineral Processing